|

|||||||||||||||||||||||||||||||

| In Utah at 801-701-1677 | |||||||||||||||||||||||||||||||

| Nationwide at 866-328-5066 | |||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Pallet Rack

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

| Pallet Rack | Interlake Mecalux Pallet Rack | Drive-thru Rack |

Tall Pallet Rack |

|

|

|

|

| Big Pallet Rack Projects | Push Back Rack | Drive In Rack | Over Dock Pallet Rack |

Pallet racking is the best storage solution for industrial applications and warehouse. Pallet rack provide sufficient storage durability and reliability for pallets and skids containing materials and inventory stock. With the right decking it can also safely accommodate and store loose items.

Pallet Rack is a material handling storage solutions designed to store materials on pallets (also known as skids), typically within a warehouse setting. There are many varieties of pallet racking, which all have horizontal rows with multiple shelf levels. Different systems of pallet racks include: drive-in, drive-thru, flow, and push-back and the regular old pallet rack you see in so many warehouses and even Home Depot and Lowes.

Drive In Pallet Racks load and retrieve from the same side, creating last-in-first-out (LIFO) inventory organization. Drive-Thru pallet rack systems load from one side and unload from the other side to create first-in-first-out (FIFO) inventory retrieval with forklifts.

Pallet Flow Pallet Rack Systems use gravity to move pallets on smooth rolling metal skate wheels on sloped rails. Push-back pallet racks use a dynamic rail system, in which deeper pallet loads automatically advance to the aisle, when the front pallet load is retrieved. Push-back pallet rack systems offer similar storage density as drive-in pallet rack, while improving selectivity and accessibility.

It can be difficult to order the correct sizes, dimensions, and weight capacity. Call our experts and let us do it all. This is a free, no obligation service that NationWide Shelving provides with all our products. Get it ordered right the first time!

Regular-Duty Pallet Rack Uprights (16-Gauge):

|

Heavy-Duty Pallet Rack Uprights (14-Gauge):

|

|

|

Step Load Beams:

Beam length is traditionally measured by the clear span between the uprights, and beam capacities are based on an evenly distributed load. Two beams are necessary in order to create a shelf.

Improved Upright and Beam Designs are almost all interchangeable with almost all manufactures and brands of pallet racks.

Uprights can be shipped assembled or unassembled (upon request)

16-Gauge Regular-Duty Uprights |

|||

| Model Number | Height | Depth | Weight |

IU36096 |

8' |

3.0' |

48 57 70 |

| IU42096 IU42120 IU42144 |

8' |

3.5' 3.5' 3.5' |

50 58 73 |

| IU48096 IU48120 IU48144 |

8' 10' 12' |

4.0' 4.0' 4.0' |

53 61 77 |

14-Gauge Heavy-Duty Uprights |

|||

| Model Number | Height | Depth | Weight |

IUH36120 |

10' |

3.0' |

73 88 110 114 |

| IUH42120 IUH42144 IUH42180 IUH42192 |

10' |

3.5' 3.5' 3.5' 3.5' |

75 91 112 120 |

| IUH48120 IUH48144 IUH48180 IUH48192 |

10' 12' 15' 16' |

4.0' 4.0' 4.0' 4.0' |

77 95 118 123 |

| Step Load Beams - Box Beams | ||||

| Model Number | Height | Length | Cap. Per Pair | Weight |

215-IB35096215-IB40096 |

3.5"4.0" |

8' |

3,460 |

25 |

| Additional Accessories for Pallet Rack: | |||

|

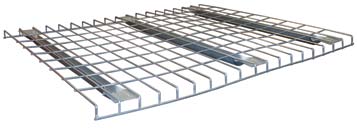

Wire Mesh Decking:

|

|

Steel Safety Supports:

|

|

Frame Guards:

|

|

Bay Dividers:

|

|

Label Holders:

|

|

|

| Wire Mesh Decking | ||||

| Model Number | Unit Depth | Deck Width | Capacity | Weight |

| 215-DF3646 215-DF3658 |

36" 36" |

46" 58" |

2,500 2,300 |

19 22 |

| 215-DF4246 215-DF4258 |

42" 42" |

46" 58" |

2,100 2,200 |

22 27 |

| 215-DF4846 215-DF4858 |

48" 48" |

46" 58" |

1,800 2,100 |

24 30 |

| Bay Dividers | |

| Model Number | Weight |

| 215-ID01 | 11 |

| Steel Safety Supports | ||

| Model Number | Upright Depth | Weight |

| 215-USS36 215-USS42 215-USS48 |

3.0' 3.5' 4.0' |

5 6 8 |

| Frame Guards | ||

| Model Number | Guard Height | Weight |

| 215-ICP24 | 24" | 11 |

| Adhesive Labels | ||

| Model Number | Size | Qty. |

| 215-L335 215-L346 |

3" x 5" 4" x 6" |

50 50 |

| Magnetic Labels | ||

| Model Number | Size | Qty. |

| 215-L335M 215-L346M |

3" x 5" 4" x 6" |

50 50 |

| Magnetic Labels | ||

| Model Number | Size | Qty. |

| 215-L335M 215-L346M |

3" x 5" 4" x 6" |

50 50 |

Order by Phone!

866-328-5066

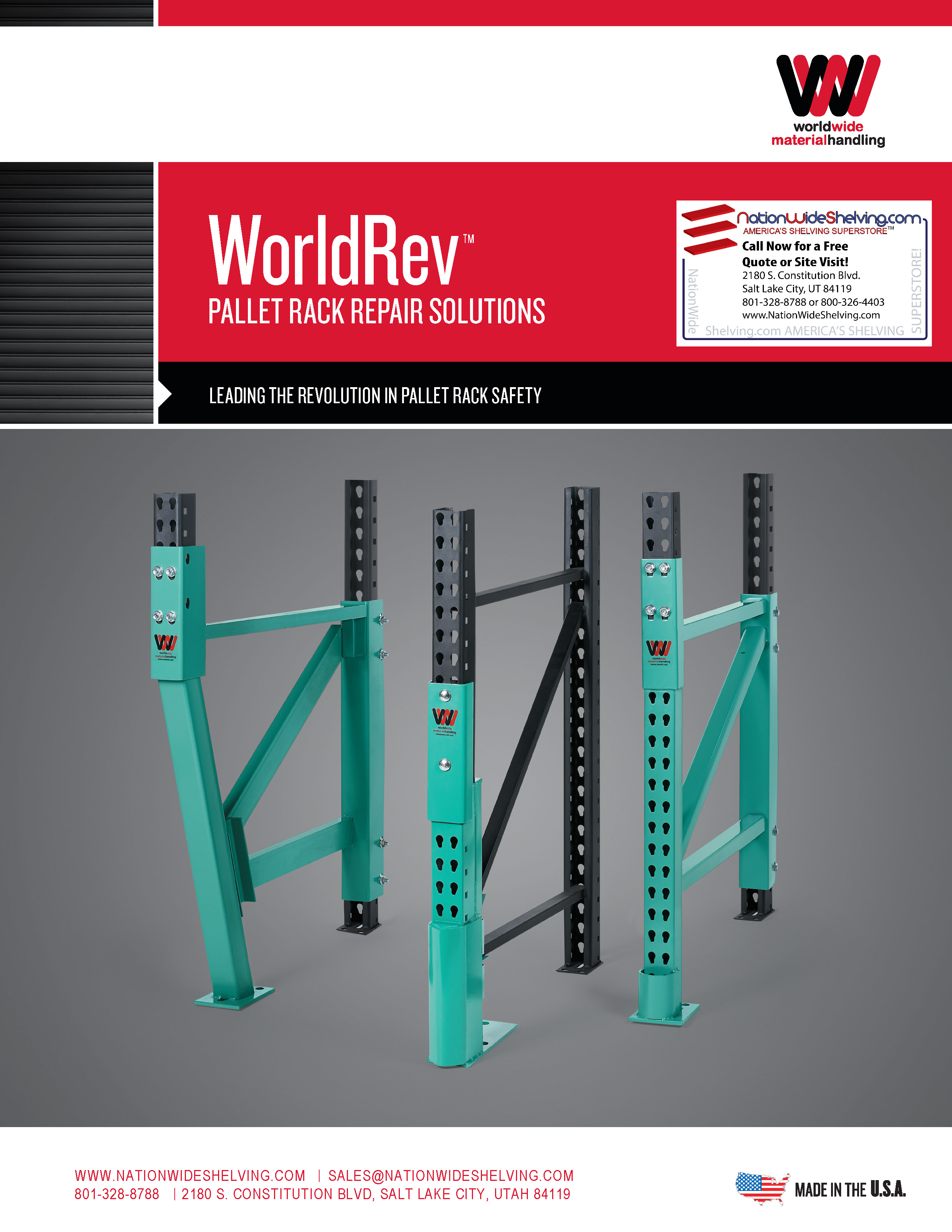

Do You Need Pallet Rack Repair Solutions?

Need Pallet Rack Repair? WE can help! We offer a solution for damage done to a pallet rack.

With Pallet Rack Repair Solutions, you are able to repair your pallet rack, rather than replacing it.

Pre-engineered or custom designed

Covers all types of pallet racks

Most repairs completed within 30 minutes or less

Repairs can be completed without unloading the rack

WorldRev S

Durable steel construction

No welding needed, all bolted

Heavy duty powder coat finish

Custom colors and heights

WorldRev SPro

All WorldRev S features included

V-Nose deflector to protect against damage done by a forklift

Heavy-duty footplate

Eliminates column twisting with two anchors

Flush-mounted deflector for very narrow aisle uses

WorldRev XS

6 inch repair kit with a deflector to help prevent future damage

No welding required

Steel construction

Powder coat finish

Footplate included

WorldRev ST

Heavy duty bracing

Straight Leg modular frame repair kit

Bullnose deflector to help prevent load wheel damage

All bolted design, no welding required

WorldRev SL

All WorldRev ST features included

Slope Leg modular frame repair kit

C-channel structural bracing

Slope Leg design allows for additional aisle clearance

Designed for back-to-back row applications only

Begin by standing the uprights by the width of the beams. If the rack is up against a wall make sure there is adequate distance behind the rack for the pallets to fit without hitting the wall. Lift a beam to the hight you need for your product with good clearance and insert the rivet into the teardrop hole of the upright. Use a rubber mallet to tap the beam firmly into the keyholes. Repeat until you have all the beams in place. Uprights should be bolted to the ground. in many areas they need to be installed per specifications listed stamped engineer drawings. This can require specific length, diameter and grade anchors you will find in the calculations In some cases a building permit will also be required. If you have any questions on this please phone us at 866-328-5066 for information for your area and project. This is just to give you an idea of the process. Pallet Rack should be installed by a professional trained in the installation of rack and all local code requirements for things like hurricanes, tornadoes, earthquakes or other mother nature or man made disturbances.

A common question about pallet rack is which pallet racks beam is right for your application. For standard racking 8 foot beams are great and you will get 2 pallets on a shelf. If you to go to a 12' beam you can get 3 pallets on a shelf. We also carry 9, 10, 12, and 14' beam for various applications. One thing to remember is the length of the beam starts inside the bracket that attaches to the upright so the overall is a bit longer. It does not include the clip at the end. The safest way is to measure the distance between your upright. That will ensure that you get the correct length on the beam that you order.

Each beam has a "step". The step allows for 2 x 4's or decking to sit down in the step so the deck is flush with the beam. This allows you to slide pallets or your inventory on and off without getting snagged.

How do you know what is the right capacity being for your application? 1st thing to remember is that the longer the beam gets the more likely it is to deflect or sag when you load it up. Evenly distribute the weight load across the length of the beam. Generally the thicker the beam the greater the capacity. The profile which is the face of the beam is where you can see the thickness. Beams range from capacities if about capacity 5047 pound capacity we have been that go all the way up to 11000 pounds and beans with latest 2500 pounds then you know what you need For assistance please call one of sales professionals and we will help you figure it out. Save yourself a surprise. Use a professional!

Do you want pallet rack in the color of your company or even university or school colors? We can make that happen. With todays flexible manufacturing processes we can custom paint you pallet rack. In fact its not the plain old green uprights and orange beams anymore. There are manufactures who can supply a wide variety of standard colors.

Order by Phone!

866-328-5066

For more details on Pallet Rack, call NationWide Shelving at 1-866-328-5066 or Email us at Info@NationWideShelving.com

Jaken

United Material Handling

UMH

Ridg-U-Rak

Steel King Industries, Inc.

Advanced Equipment Company, Inc.

Specialized Storage Systems Inc.

American Material Handling Corp.Atlanta Pallet Rack

Advance Storage Products, Div. of J.C.M. Industries, Inc.

Bulldog Rack Company

Frazier Industrial

Hannibal Industries, Inc.

Husky Rack & Wire

Interlake Mecalux Inc.

Nedcon USA Inc.

Ningbo Xinguang Rack Co, Ltd.

Rack Builders, Inc.

RACKUSA / Tear Drop Rack

Speedrack Products Group, Ltd.

SpaceRak, Division of Heartland Steel Products, Inc.

Unarco Material Handling, Inc.

United Material Handling, Inc.

Xiamen Luckyroc Industry Co,.Ltd.

Ridgi-rack

UMH

NAWL

Teilhaber

Space Rack

Spacesaver

Stanley Black & Decker/Vidmar

Worldwide Material Handling

Global Industrial

Tri-Boro

UniRak

Nashville Wire (Decking)

Vestil (Structural Rack)

Industrial Netting (Pallet Rack Netting)

Beastwire/Space Guard (Pallet Rack Guarding and Caging)

ExGlobe (Pitch and Spring Rail Rack)

ITC (Galvanized Pallet Rack & Accessories)

Speed Cell (Pallet Rack Organizer Hanging cells)

Interlake (Original Style)

USP

Lodi Metal-Tech

Steel King

Shoppas

Ridg-U-Rack

Teilhaber Penco

Interlake

Durham, Nashville Wire

Mecalux

Ohio Rack

Rid-u-Rack

Tier-Rack

Artco (Tube) Pallet Rack

Buckley Pallet Rack

Burtman, Structural Pallet Rack '

Altrui Pallet Rack

Dexion Pallet Rack

EMI Pallet Rack

Frick Gallagher Pallet Rack

Husky Crashguard Pallet Rack

Inca Pallet Rack

Lok-Rack Pallet Rack

Palmer Schile Pallet Rack

Sammons/Bloom Pallet Rack

Unarco II Pallet Rack

Keystone Style Pallet Rack

T-Bolt (Unarco) Pallet Rack

Speedrack Pallet Rack

Paltier Pallet Rack

Structural Pallet Rack

Sturdi-Bilt Pallet Rack

Ridg-U-Rack Pallet Rack

Webb/Slide-N-Lock

Hiline Pallet Rack

Penco Pallet Rack

Amerlok Pallet Rack

Artco Pallet Rack

Buckley Mastorak Pallet Rack

EMI Air-Row Pallet Rack

Engineered Products Pallet Rack

Frick Gallagher Pallet Rack

Hallowell Pallet Rack

Hi-Line Pallet Rack

Husky Pallet Rack

Inca Backbone

Konstant Pallet Rack

Lyon Pallet Rack

M-I-Rak Pallet Rack

Mecalux Pallet Rack

Nedcon Pallet Rack

Palmer-Shile Pallet Rack

Paltier Pallet Rack

Prest / Jarvis-Webb Pallet Rack

Redi-Rack Pallet Rack

Republic Pallet Rack

Sammons Pallet Rack

Speedrack Pallet Rack

Structural Pallet Rack

Frazier Structural Pallet Rack

Sturdi Built Pallet Rack

T-Bolt Pallet Rack

Unarco II Pallet Rack

Need a brand you don't see listed? Please phone in to see if we carry it.

FAQ

Q: What are the standard beam widths?

A: 8, 9, 10 and 12 feet

Q: What are the standard upright heights?

A: 8, 10 ,12, 15, 16, and 20 feet high

Q: What are the beam capacities?

A: Beam capacities vary greatly from light weight capacities to extremely heavy duty. Common requirements are 3,500 to 7,000 pounds.

Q: What size columns do uprights have?

A: 3" x 3", 16 gauge and 14 gauge

Q: Are there seismic foot plates?

A: Yes, 5 " x 8"

Q: Is wire mesh decking available?

A: Yes, in a wide variety of sizes to match beam widths and depths.

Q: What is the weight capacity of the uprights?

A: Uprights range from 16,000 to 24,000 pounds.

Q: What colors are available?

A: A variety of colors are available depending on manufacturer.

Q: What style of upright holes are available?

A: Tear Drop

Q: What are typical depths for pallet?

A: Rack depths of 36" 42" 48" are typical but others are available, please call.

Q: Are frames bolted or welded?

A: They can be either. In the US welded is more common while worldwide bolted are more common.

Q: What accessories are available for pallet rack?

A: Post frame guards, row spacers, safety supports, label holders, bay dividers, steel and wire decking, safety netting, and many more.

Q: What is palletized Storage?

A:

Q: What is a bay in pallet Racking?

A:

Q: What is palletized storage?

A:

Q: What is a bay in pallet racking?

A:

Q: What is the minimum clearance between pallets and a racking structure?

A:

Q: What is push back racking?

A:

Q: Where do you store pallets?

A:

Q: What are the different types of pallet racking?

A:

Q: How much does used pallet racking cost?

A:

Q: What are the different types of racks?

A:

Q: How does pallet racking work?

A:

Q: How do you determine the capacity of a pallet rack?

A:

Q: How do you anchor a pallet rack to concrete?

A:

Q: What is a high rack?

A:

How much does used pallet racking cost?

How much weight can I put on a pallet rack?

How do you stack pallet rack beams?

How do you measure a pallet rack?

How tall is pallet racking?

How much space do you need between pallet racks?

Do pallet racks need to be bolted to the floor?

How do you make a pallet rack?

How do you design a warehouse rack?

How do I calculate the cost of a pallet?

What are pallet positions?

What is teardrop pallet rack?

Distribution Centers

Warehouse and Manufacturing

Pallets

Furniture, Table Tops Without Legs

Bulk Items or Large Materials

Tubs and Drums

Medical Supplies

Nutritional Supplements

Automotive Parts

Hydaulic Oil

Carpet

Truck Parts

Furniture

Sinks

55 Gallon Drums

Car Parts

Motor Oil

Title

Tractor Parts

Paint

Wire Spools

Cases and Boxes

Fencing Parts

Plumbing Supplies and Stock

Sprinkler Supplies and Stock

Baby Clothes

Orbit Sprinkler Parts

Nutrition Supplement Picking and Storing

Raw Candy Ingredients

Street Sign Storage

Yoga Mats

Billiards and Game Room Stock

Marijuana

Cannabis

hemp

Pallet Rack Case Studies:

Storage of Phone Equipment on Pallet Rack

Pallet Rack Shelving for Storage of Parts to Assemble and Store High Tech Medical Procedure Equipment

Bio Repository Storage Racks

Top Primary Industries

Using

Pallet Rack:

We will list some top Industries using pallet rack but almost everyone uses rack!

Government

Industrial

Commercial

Manufacturing

Pallet Rack Literature Brochures

and Catalogs:

United Material Handling Pallet Rack Brochure

Advanced Structural Pallet Rack Brochure

Advanced Carton Flow Pallet Rack Brochure

Jaken FastRak Bulk Storage Shelving Brochure

Jaken Stock, Reel & Tire Racks Brochure

NAWL: North American Wholesale Logistics / Spectrum Quick Ship Pallet Racking Brochure

World Rev Pallet Rack Repair Brochure

SpaceGuard Pallet Rack Safety Mesh Guard Brochure

Sammons Style Pallet Rack Brochure

Jaken Bulk Rack Brochure

Jaken Boltless Rivet Shelving

Interlake Mecalux Pallet Rack Brochure

Unarco Pallet Rack Brochure

Interlake Mecalux Drive In Pallet Rack

Interlake Push Back Rack Brochure

Bulldog Cantilever Rack Brochure

Bulldog Pallet Rack Brochure

Customers Who Searched for Pallet Rack

Also Searched for:

Flow Rail Pallet Rack Systems

Push Back Pallet Rack

Structural Pallet Rack

Pallet Rack Repair

Pallet

Rack Beams

Pallet Rack Uprights

Pallet Rack Wire Decking

Galvanized Wire Decking

Teardrop Pallet Rack

Pallet Rack Guarding and Caging

Narrow Aisle Pallet Rack

Drive In Rack

Push Back Rack

Gravity Flow Rack

Mobile Racking

Shuttle Racking

Conventional Pallet Rack

Pallet Racking

Types of Racking System

Pallet Racking Configuration

Warehouse Racking Layout

Industrial Racking System

Pallet Flow Rack

Installing Pallet Rack:

Pallet Rack should be installed by a professional installation company skilled in the install of pallet rack. Like so many products it seems simple on the surface but everyone who uses it relies on the proper installation. In traffic areas with many transactions and staff moving around it and product moving on and off with for trucks, pallet jacks and other equipment it needs to be be stable in all situations. Plus local building codes need to be enforced to make it sake for your staff and others entering your work areas where the rack is installed and used. OSHA has many safety requirements that update and need to be checked when installing pallet rack. Some include anyone working more than four feet off the ground need fall protection. installers many also need gloves and hart hats. Due to the weight some uprights and beams may need a group lift or mechanical way to move the rack into place. Pallet Rack should be installed square and plumb. A 1/8 inch vertical variance is acceptable per four feet of rack. Square each section and check with a level. Anchoring has become very specific from area to area to comply with code. It is getting very difficult to get used rack to conform with local building codes upon installation and can cause great frustration when someone has purchased used rack to save some money then found out they need to scrap or resell it and purchase new rack to meet current building and earthquakes codes.

The History of Pallet Rack:

If you ever saw the movie Michale with John Travolta he had a great line. Something to the effect that he invented lines, before that people were just milling around. Funny! Pallet Rack was kind of the same way. From the earliest of times people were making shelves to store what they could put up by hand but heavy items just kept sprawling around taking up floor space and getting in the way. Wood was easily available to make pallets to set heavy and bulk packaged inventory and supplies on to keep them off the floor and safe from flooding and other natural events that could rust or ruin products. But before pallet rack things were just laying around taking up space!

In 1914 corrugated packaging came on the scene to help with packaging bulk items for storage.

Building more space has always been expensive and difficult. Plus you need to heat it and take care of it. Time spent away from the core business that allowed people to make their living. Then came equipment to lift these heavy items and allowed for a heavier shelf, Pallet Rack, to emerge. Forklifts were developed by several companies out of the crane concept around 1915. Once they hit the market the race was on to develop a rack to set the heavier or bulk boxes on to clean up floor space. It was really a perfect storm as Andrew Carnegie was bringing quality and well priced steel to the market which allowed so may products to develop and emerge. As time went by standards evolved for the wood pallet and forklift to work together which allowed for more standards in building pallet rack to house the pallets and allows for easy loading and unloading.

Over time Pallet Rack has evolved into two major types. Structural Rack and Selective Rack also called Roll Formed Rack. Selective and roll formed is very common in warehouses and the major difference is selective rack generally is also the "skin" for new construction allowing a lower cost construction for a warehouse that will be filled with rack as it can significant lower the construction costs associated with the skin or walls. Even in todays world of heavy automation rack has stood the test of time and is still the mostly widely used from of storage in a warehouse.

Step beams are common since they allow the wood or steel decking to fit in to hold pallets or whatever is stored on the rack.

As different forklifts have evolved and space becomes more important than ever very narrow aisle rack VNA where the rack is set very close together to maximize space for storage is becoming more common. In most cases it works with automated pickers so no human error can occur in the narrow aisles.

Common Pallet Sizes for Industries by MH1, 2005

Grocery Pallets: 48 x 40

Chemical Pallets: 42 x 42

Military Pallets: 40 x 48

Beverage Pallets: 36 x 36

The Future of Pallet Rack

There seems no end to the future of Pallet Rack for storage in business. As e commerce and the world wide economy grows the need for massive and dense storage to get stronger and stronger. Robotic retrieve of goods is being built around pallet rack as the central storage product. The robot puts the product away and retrieves it but it is still stored on the rack. Rack is getting more specific to accommodate taller and taller applications. there are many DYI uses for used pallets associated with the use of pallet rack and these are great ways for all of us to participate in keeping all those pallet out of landfills.

Decking Options:

2 x 4 's

Wire Decking

Solid Deck

Pallet Flow Rollers

Engineered Products makes a wide variety of options to compliment your rack:

Flex Track - manufactured in plant in Greenville south Carolina. carton flow flex track is on the rise in sales across America!

30 engineers in the office to help you design your .......

select track. if 12 trays inside of a bay they will have 12 hangers. now they make one hanger to go all the way across to one hanger to lift out. see brochure.

can have a lane divider. products tend to flow diagonally just fine.

tray sits on beam and lift right in and out of there.

flex track mini

product sit inside of frame becoming flush with bay.

1900series 3000 series

plastic skate wheel or metal wheel

brake can be implemented.

beverage distribution

flow racks drop right in without tools

EP has product specific for handling kegs. rollers are designed to work with kegs and keep them safe as they roll down the line.

Carton flow about a third of business, in business 66 years.

EP's main business is as a structural rack manufacturer. They do provide knock down rack for east coast.

Nordstrom uses 20 bay high - 300 feet long

unit load, mini load shuttle systems

textile racking

dock racks to store pallets above dock doors

deep lane shuttle systems

unit load shuttle systems

pick deck

integrated safety deck with pallet flow

Pallet Flow can be manufactured to drop right in during installed on existing rack. EP has lanes. rollers are available from other manufacturers. Interlake makes one , concentric makes one.

Information to help you pick the best rack.

Pallet rack can all look just about the same. You've rolled down the lanes at home depot and if you are on this page have likely seen rack and used rack. So what makes it different? The best thing to do is call in and talk to a representative who can assess your requirements and suggest the best rack to you for your application.

But here are a few ideas for you to give you idea of why a rack salesperson be be of value to you and make you life much much easier! Say the column in rack you are considering are all 3 inches. Well total strength can be determined by many factors. The amount of braces can help strengthen rack. The type of steel is a big factor in determining strength. Some steel is stronger than others. How good are the welds? Some use a closed tube design but most leave a seam which is perfectly fine in most situations and can save you money. You can combine these so any one attribute combined with another can make one or the other superior in load bearing capacities. The closed tube designs can give you up to 250% more frontal impact strength and 68 percent greater side impact resistance than open back styles.

Roll formed rack is made from cold rolled steel and structural rack is made from hot rolled steel. It is exactly as it sounds. One is bent cold the other is done while the steel is red hot. Hot rolled is stronger. Cold rolled rack can be lighter which is important for install costs and shipping. Cold roll is generally rated to about 7,000 pounds and hot rolled structural rack can handle upwards of 30,000. pounds. Quite a difference but will you need to pay for that? Often the answer is no. Quite often in fact. But your application could make the hot worth it for life and safety.

Ease of assembly can also be a factor, and more and more of a factor these days.

Call 866-328-5066 and talk with a pallet rack professional!

The Projected Future of Pallet Rack.

Pallet Rack sales world wide are projected to grow to 7 billion dollars by 2026! Demand for pallet rack is being driven by many factors including increased demand for products like drugs, food and drink, automobiles and textiles. Other factors include increase rents and mortgages of commercial building driving companies to make better use of floor space. In the us market expansion of exports and e commerce require more goods to be stored on rack.

Pallet Rack is designed to provide highly efficient storage of countless parts for, inventory, distribution centers, automotive, assembly and storage needs. Pallet Rack is used for palatalization of goods and material for distribution and can also be set up for storage of loose goods and material.

Even large retailers have found pallet rack a good looking and inexpensive way to display stock for customer purchase. From a few beams to large installations connected to complex automated storage and delivery systems we can help you determine what you need. Nationwide Shelving can also help you determine if your application and productivity would be better served with either more space efficient solutions or faster picking solutions such as drive in rack, push back rack and gravity flow racks. Our highly trained designers will insure you get the right rack and the most possible storage. From simple to complex solutions for all forms of shelving, including sophisticated multi-level, automated and modular applications we are America's Shelving Superstore for a reason!

Pallet Rack provides high capacity storage for everything from light duty to your heaviest pallets!

You can choose how many levels you will need for your products.

Pallet Rack can be purchased with a start unit and add ons. so you can always reconfigure and add on to your pallet rack. Assembly is very easy with Boltless assembly. Additional beams can always be purchased to add levels. Requirements do change these days so pallet rack is very adaptable. Many kinds of decking are available including wire decking and wood decking. This works well for times not stored on pallet or where leakage could occur as wire decking makes cleaning easy. Need extra support for your pallet rack? Cross bars are available!

Dividers can also be installed on the wire deck to keep contents organized. Row spacers can be installed between rows to keep space between uprights. Wall brackets can also be added to increase stability and safety. Uprights include floor brackets to mount rack to the floor for stability. seismic floor plates are available.

Contact Us | About Us

Copyright © 1997-2026 All Rights Reserved